Miniaturisation and Optimised Integration

Smart Solutions for an Optimal Use Concerning Miniaturisation

Miniaturisation is a driving factor influencing electronics. Small and light-weight equipment and assemblies are required. On the one hand the structures on the PCBs are becoming more and more finer in order to be able to cater to the smaller connection grids of high performance components too. On the other hand the assembly spaces are frequently so minimised that the printed circuit boards are “folded in” as rigid-flex variants, or power and control electronics which used to be mainly separated are combined in just one single circuit board.

Unimicron Germany offers many solution concepts for optimising integration.

HDI-Technology - HiDensity PCB

Miniaturisation in electronics is making ever higher demands of printed circuit boards, especially concerning conductor widths, distances and pad density in Ball Grid Array areas.

Applications:

- Network technology

- Medical technology

- High frequency technology

Advantages:

- Space savings

- High reliability

- Combination with nearly all other technologies possible

Semiflex-Technology - Semiflex PCB

Semiflex offers an alternative with considerable cost advantages over classic rigid-flex PCBs on a polyimide basis. This technology is suitable for applications only bent once during mounting of the assembly.

Applications:

- Applications with no dynamic stress of the bending area

- Automotive

- Safety electronics

Advantages:

- High reliability

- Component savings possible

- Reduction of space

IMS and Heatsink Technology -

Metal Plate PCB

IMS as well as heatsink technology are extremely efficient ways of dissipating heat from an electronic assembly. In case using heatsinks the bonded metal plate can be part of the housing concept.

Applications:

- Electro mobility and automotive

- Industrial electronics

- Lightning technology

Advantages:

- Optimal heat dissipation

- High reliability

- Combinable with all other technologies

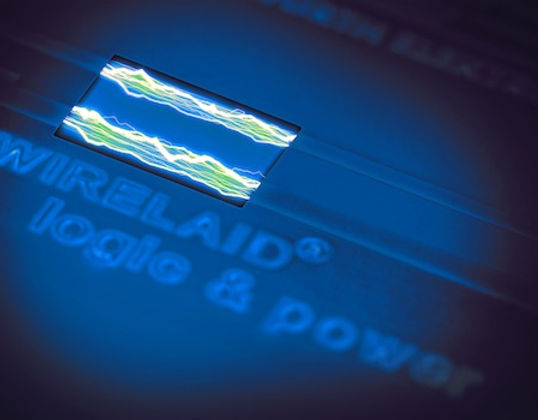

Partial Thick Copper Technology - Wirelaid®

In Wirelaid Technology copper wires are applied to the treatment side of a copper foil by micro resistance welding. It can be an cost efficiency alternative to thick copper technology.

Applications:

- Power electronics

- High current applications up to 100 A

- Semiflex version possible

Advantages:

- Combination of power and logic on one board

- Optimal heat dissipation

- Cost reduction

Thick Copper Profile Technology - HiCu Profile PCB

In HiCu Profile Technology massive copper elements, round and angular, are inserted in the inner cores of multilayer PCBs and then laminated into the PCB.

Applications:

- Power electronics

- Current carrying capacity up to 1,000 A

- Power and logic combined on one board

Advantages:

- Excellent heat dissipation

- Combination of logic and power

- Weight savings and reduction of thickness of PCB

.png)